- Product

- Solutions

Case Studies

Automotive

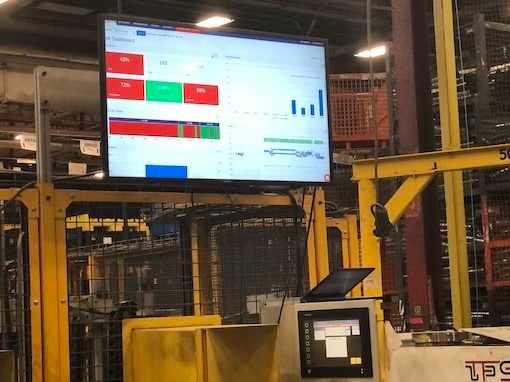

Versatech Increased OEE 30%Consumer Package Goods

Oral Biotech Eliminated ScrapFood/Beverage

Louisiana Fish Fry Increases OEE 12%Metal Stamping

H&T Waterbury Reduced Downtime 71%Blow Molding

Lyons Blow Molding Automated Reporting & Labeling - Resources

- Blog