“One of the main reasons we moved to Mingo,” Nick said, “other than visibility, is the incentive tracking standpoint,” he said.

Nick added, “It allows us to track actual to expected performance in operations, distribution, even the warehouse, based on the Mingo reporting which helps support the incentive program payout.”

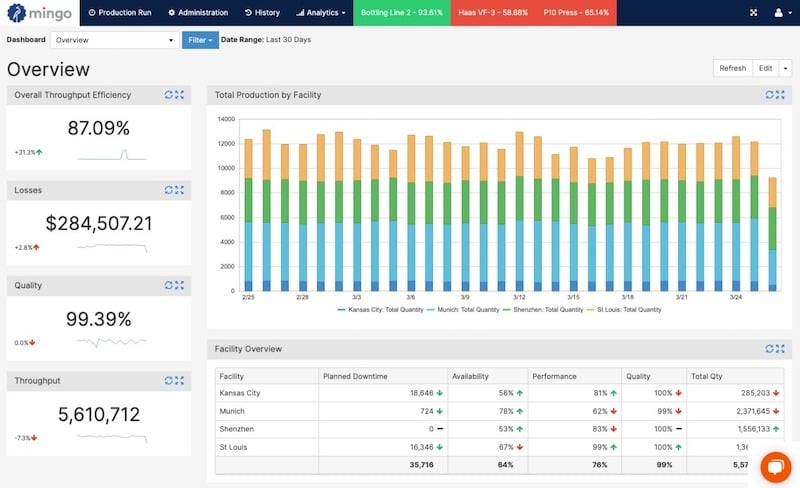

For Tacony, Mingo is also a goal tracking software to understand what’s going on at an operational level.

“From my perspective, metrics are different based on the product because each product itself is different and has different ways to measure the efficiency, and there is a complexity to it, but the way we built it, it’s very easy to interpret,” said Nick, “Because green means green across the board at Tacony, whether you’re building it customized or building it to the shelf.”

If an operator looks at the operator screen or scoreboard, and it’s red, they immediately know they need to get back on track, enabling the operator to be in control of their own progress.

“You know from the minute you press the start button in the morning if you’re tracking towards your goal.”

With the “know where you stand mentality”, management can easily walk around, make decisions quickly, and “win the day” by moving a bit of production around to hit the target.

“We have the ability to really dive into jobs and efficiency that way,” Ben said. “It’s powerful data.”

Mingo creates a work environment that encourages communication and employee empowerment.