Competitor Comparison

Choosing a manufacturing software solution is hard. There are many, many options. Depending on your goals, it may be hard to select the right one.

Mingo Smart Factory and MachineMetrics are two software solutions purpose-built for the manufacturing industry. We’ll lay out the similarities and differences between the two so you’re able to determine which will be a better choice for your company.

As we mentioned, both manufacturing software solutions can help manufacturers get visibility into the plant, but there are a couple of key differences between the two.

Mingo is a complete solution, providing everything from sensors and IoT hardware to pre-built dashboards and mobile alerts. With MachineMetrics, you will need to provide your own sensors and connectivity solution. It does not come pre-packaged out of the box.

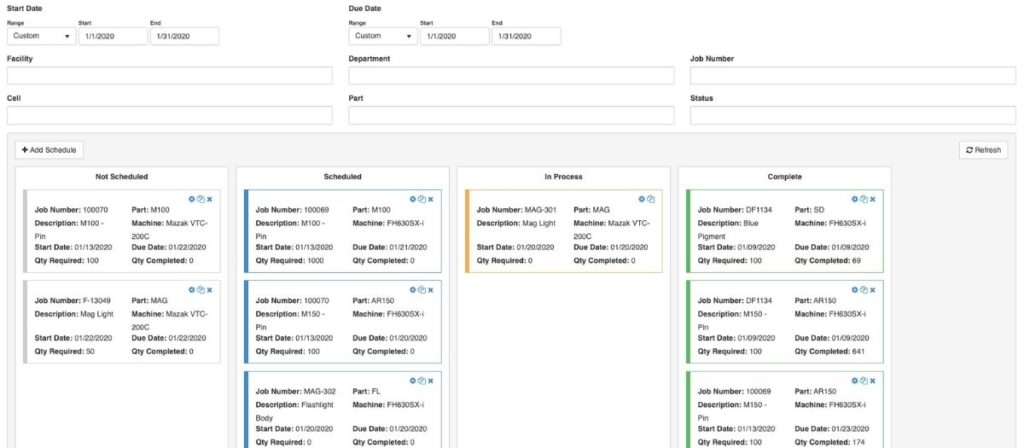

Additionally, Mingo can give you a bird’s eye view of how the plant is performing, or you can look at each station or machine on a line individually with the line configuration capability. Then, you’ll be able to easily monitor downtime, identify and correct bottlenecks, and get unit of measure support. Scheduling is also one of the big differentiators. This gives manufacturers the ability to optimize and plan to schedule, easily. You can track how close production is to schedule while also providing operators with the knowledge of where they stand at any given time.

Both Mingo and MachineMetrics are specifically for the manufacturing industry. This includes industry verticals like food and beverage, plastics, consumer packaged goods, aerospace, automotive, and so much more.

There is one main difference, however. MachineMetrics can be used in the oil & gas industry which is considered process manufacturing. Mingo focuses solely on discrete manufacturers, creating a highly focused, inexpensive solution for a specific group of people. As long as you produce a tangible product, as done in discrete manufacturing, Mingo can help you get visibility into your plant.

“Why is this an important distinction to point out?”, you may be wondering. Well, by prioritizing the needs of a specific type of manufacturer, Mingo is able to design the discrete manufacturing software with their needs in mind. It is purpose-built for the challenges discrete manufacturers face every day rather than trying to bend software to their needs. It’s flexible and customizable.

Intended to replace overly complex and expensive traditional solutions, Mingo helps manufacturers get visibility and calm in the plant. It’s a complete solution that is both easy-to-use and flexible. Data can be collected via machine, sensors, or people, contextualized, and translated into actionable insights, giving you the ability to make data-driven decisions. With Mingo, you will know exactly how the floor is running, increase productivity, improve efficiency, and generate revenue.

We understand the choice of manufacturing productivity software is a tough one, but we’ve compiled a few additional resources that may help you make a decision.

There are many, many manufacturing software options which often results in choice overload. It can be difficult to know which software is going to be the best fit for your company. At the end of the day, you need a solution that is going to help you get visibility into the plant and solve problems. While we would like to persuade you to choose Mingo, we know that you need to come to your own conclusions. That said, we strongly encourage you to outline your goals – what do you hope to accomplish by implementing a manufacturing productivity solution?

When you have those goals written down, it will become much easier to evaluate your choices. We recommend watching demos, combing through resources and blogs, evaluating different solutions via review sites like Capterra or SoftwareAdvice, and scheduling calls with each software’s sales team. The information you collect will give you much more insight into which option is going to better fulfill your needs.

When you’re ready, we’ll be happy to provide additional information. Watch a free demo or schedule a call with our team of experts.

Built by people who know manufacturing, Mingo provides the 21st century “Smart Factory” experience that manufacturers need to grow in a modern environment. See how it can help you drive revenue.

You need visibility into your plant. Sure, you need to solve problems, too, but all of that problem-solving starts with getting visibility into how your machines and people are performing. Mingo gives you that visibility.

Production planning and scheduling gives you the flexibility to plan, track, and understand where you stand, in real-time.

Layout and model a production, getting information on every station or the line as a whole, in a single view.

Collect process data, giving you the ability to detect anomalies. Get notice of irregular changes, such as a change in temperature or vibration on a machine.

Mingo is a complete solution and provides everything you need to get up and running in less than 1 day. With sensors, dashboards, iPads, and a mobile app, you won’t need to outsource.

Built by people who know manufacturing, Mingo Smart Factory provides the 21st century “Smart Factory” experience that manufacturers need to grow in a modern environment. See how it can help you drive revenue.

© Copyright 2024 Mingo Smart Factory » Privacy