Daily production meetings are crucial to the success of a manufacturer, not only to achieve goals and solve problems but to create an engaging, transparent culture. But, not all manufacturers have production meetings, and if they do, they likely are not effective or helpful.

A daily production meeting can transform an organization. “Essentially, the morning meeting embodies open communication and dialogue to keep people engaged,” Nick Hinman, VP of Corporate Strategy at Tacony, says. “If you stay connected at the right level, the right goals are established, and the right tracking is in place, the rest will follow.”

In this blog, we’ll define daily production meetings, outline the length and structure, provide a list of key attendees, help to outline the data you should be looking at, and where this meeting should be held.

Overview of Daily Production Meetings

What is a daily production meeting?

What data should be looked at?

Where do you hold the meeting?

Why you absolutely need a daily production meeting

What is a Daily Production Meeting?

The best-run manufacturing companies have daily production meetings. These quick, 10-15 minute meetings are designed to provide an overview of progress and keep everyone aware and engaged of what’s happening in the plant.

The purpose is to make these quick, not taking up too much time as these are non-value-add activities (yet, they still provide so much value to the organization) while providing a snapshot of what’s happening.

- What went right?

- What went wrong?

- What are we going to do about it?

What is the Structure of a Daily Production Meeting?

Nick Hinman offers insight into daily meetings held at his plants, “Most importantly, we make sure these meetings are consistently held, in every plant. Both manufacturing and our warehouse and distribution areas are included. These meetings are very simple. We look at:

- How did we do yesterday?

- What do we have to do today to improve from yesterday?

- Is there anything we need to talk about of importance or that we need to accomplish as a team?”

Beyond these initial three questions, ideally, the structure of a daily production meeting follows the macro, mega, and micro (or tiered) organizational idea.

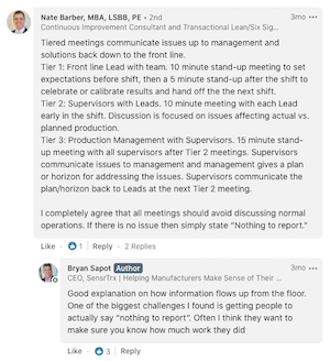

Nate Barber, a Continuous Improvement Consultant at Opgrade, provided input into the importance of structuring daily meetings into tiers, which are also summarized in a recent blog “LinkedIn Experts Debate: Outdated Whiteboards and Effective Production Meetings in Manufacturing.”

Micro (Tier 1)

This is a daily huddle shift hand-off with operators and supervisors. During this meeting, you talk about what went right and what went wrong the day before. If something went wrong, what can be done today to improve? The use of data in these meetings will help determine what happened and what needs to be done to correct problems that occurred, creating a data-driven culture in the process.

Set expectations ahead of time so everyone is on the same page.

This is also the place to talk about maintenance activity. Discuss how many defects were found. Determine which are critical and which can be handled another day. This helps maintenance determine a work plan for the day and keep everyone aligned and aware of the tasks at hand. Ask questions like:

- Who’s escalating it?

- Who’s solving it?

- Who’s checking that it actually happened?

This not only creates awareness throughout the plant but involves the production team regarding what is happening on the maintenance side.

And most importantly, talk about wins whether in production, maintenance, or otherwise, with everyone.

It’s also important to have some sort of feedback system to make sure you’re tracking those issues you know need to be worked on. Is this a one-time thing or an ongoing concern? Whether this is a whiteboard, Excel document, or software, tracking is essential to ensure tasks are completed but also improved upon.

Macro (Tier 2)

In this tier of meeting, supervisors are communicating with leads about issues affecting planned vs. actual production. Are you on schedule or behind? What can be done to meet demand if currently behind?

Mega (Tier 3)

And, finally, the last tier focuses on communication between the production management team and supervisors. After the Macro Tier 2 daily huddle, supervisors communicate issues back to management and then management provides a plan for addressing those issues. The supervisors relay the information back to their employees.

Manufacturers could even go a step further and conduct weekly production meetings with the plant or general manager. Ideally, this meeting focuses on the plant’s performance at the end of every week and if goals were met or not. If not, a plan of action is determined to ensure goals are met the next week.

The benefit of structuring daily meetings in this way is that the entire organization, regardless of role, can see there is cadence and accountability from top to bottom. Habits and behaviors are formed that create continuous improvement and continued success. Employees will see how their activities align with organizational goals. The alignment further encourages achieving individual goals.

Even if there is nothing to report, that should be said during the daily production meeting. When employees are comfortable reporting “nothing”, that’s a tell-tale sign of a culture that trusts and supports its employees.

And, remember, while daily production meetings are intended to provide an overview of the plant’s progress, it’s important to acknowledge the efforts and work of your employees. Words of encouragement matter.

Who Should Attend?

Like we mentioned above, meetings can take a tiered approach, including different people at the different levels, but everyone in the plant must be involved in at least 1 of these daily meetings, even maintenance. Meetings should be cross-functional.

“First off, maintenance needs to be in that meeting. You wouldn’t believe how many times maintenance isn’t in the production meetings. That’s not good. They need representation there because that’s where you should be escalating things,” Stuart Fergusson, Director of Solutions Engineering at Fiix CMMS Software says.

Everyone in the plant is important and needs to be included. Without input and communication from all teams, daily meetings would not be as comprehensive or inclusive.

What Data Should be Looking at?

An agenda with standard work should provide structure to the daily meetings. This will help to determine key KPIs without going too far into the weeds.

“During these meetings, we highlight quality issues we ran into, miss picks on the lines, customer services issues, scrap from engineering, backorders, and overall efficiency, basically all the key KPIs we track daily.

This creates awareness among the team so everyone knows where we are for the week, where we need to go, and what we need to concentrate on. We also share quick wins and if we weren’t successful in meeting KPI goals, we discuss how to do better,” Nick Hinman says.

Jesse DePriest, a Lean Transformation Coach and Director of Operational Excellence at First National Bank of Omaha, explains why defining and measuring the process is important, “Define the process. Decide how to measure that. State that challenge in measurable terms for what excellence would be. Now we can go about the business of framing the problem and target setting and obstacles for that.”

Where Do You Hold the Meeting?

Because these meetings are quick and to the point, there’s no reason to meet in a formal meeting room. Instead, hold the meeting on the plant floor or break room so progress can be reviewed and next steps can be outlined, and after, everyone begins their day.

Truthfully, there’s no wrong place to hold the meeting. Determine what is going to work for your plant. Most importantly, hold a daily production meeting and don’t worry about the location.

Tracking Action Items from the Daily Production Meeting

You’ve held a daily meeting, outlined areas for improvement, recognized big wins, and encouraged employees, so what’s next? You need to create a structure for ensuring tasks are completed and tracked.

How do you track these action items?

“As an enterprise, we should understand what our strategy is, and where we’re going, how would we do that and how do we know we’re achieving it?” Jesse DePriest explains.

Most often, tracking is very simple and done with whiteboards or a set of cards, maybe a Kanban system. That’s really it. There are so many processes that can be involved in tracking action items from the daily production meeting that simple cards are the best solution.

As a productivity software solution, we’ve even debated adding in daily production meeting tracking capabilities, but in surveying our customer base, they don’t want or need it. Every task is just a little bit different and if you were to track that in a system, it would get too complex, too quickly.

If the tracking system is really simple, it’s on a card moving through the processes, and it’s reviewed through the daily production meetings to make sure it’s getting done, there is not much more you need to do from a tracking perspective.

Many people think you need to digitize these systems, but as we’ve proven, that is simply not the case. A simple solution will prove to be most effective.

You Need a Daily Production Meeting

A daily meeting is vital to the success of a manufacturing company, not only in terms of revenue and happy customers but for a great culture that respects its people and keeps everyone engaged. “It brings meaning. I know why this is important and what we’re trying to do,” Jesse DePriest says.

And, remember, good leadership is crucial to the success of implementing daily meetings. Coaching and mentoring from good leaders will help to ensure the right behaviors and habits take root, a very important piece of a successful daily meeting. DePriest adds, “A mature lean organization will have leadership practices and behaviors that support and says we’re here to solve problems with you.”

And if it doesn’t, there are larger issues to address beyond the daily meeting.

Resources:

Videos featured throughout this blog are snippets from our podcast, Zen and the Art of Manufacturing. You can listen and watch the full episodes wherever you get your podcasts or on YouTube. Episodes and guests featured in this blog are:

- The Foundations of Lean with Nick Hinman

- Achieving Lean Success with Paul Dunlop

- The Difference Between Data and Information with Jesse DePriest