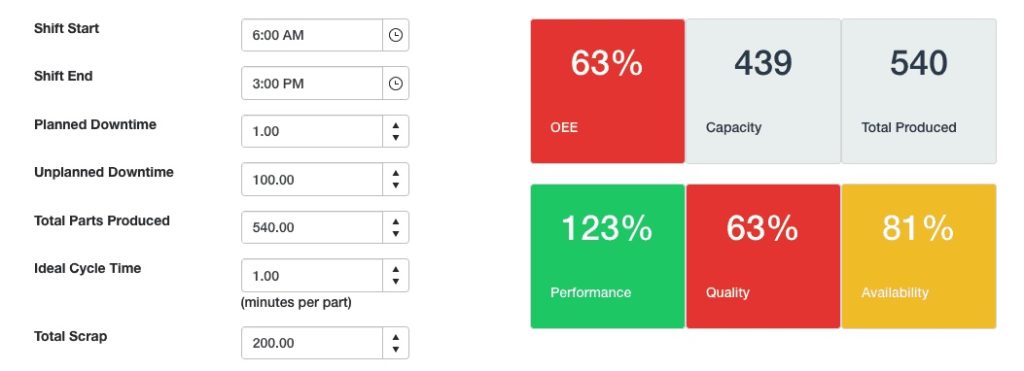

Overall Equipment Effectiveness is a vital metric used by manufacturers to assess the performance of their equipment and improve production processes. This software provides a comprehensive solution to measure and analyse this metric in real time, enabling businesses to identify and address inefficiencies promptly.

Production monitoring software provides monitoring and reporting of real time OEE metrics, allowing manufacturers to track their equipment’s performance on an ongoing basis. With this information at their fingertips, businesses can make informed decisions to drive continuous improvement and maximise their overall equipment effectiveness.

In today’s fast-paced manufacturing landscape, companies are constantly looking for ways to optimise their operations and maximise productivity. One tool that has gained significant attention and proven to be effective in achieving these objectives is OEE software. By understanding the concept of OEE software and its key features, manufacturers can implement it in their operations to enhance efficiency and drive overall success.