I’ve written a lot about OEE before: is OEE a flawed metric, is 100% OEE a myth, and why many manufacturers are wasting time trying to measure it. My expertise on the subject recently attracted the attention of a COO of a major automotive parts manufacturer who wanted to discuss this in greater depth. Ultimately, we ended up covering OEE in the automotive industry applications in a pretty comprehensive fashion.

Below, I’ve highlighted some of the key points of our conversation, what he chose to anonymously share with me, and some additional insights into OEE for automotive parts manufacturers.

COO’s on OEE in the Automotive Industry

This was my first question to the COO. His answer didn’t surprise me. Yes, of course. OEE is rightfully an important metric for automotive parts manufacturers. Additionally, it can be argued that optimizing OEE offers more benefits to automotive parts manufacturers than most other niche manufacturers.

I wanted him to share his thoughts on why OEE was critical to his business and some problems he’d recently solved related to the metric. His primary focus in describing this to me was to highlight just how critical measuring and understanding performance and uptime were to his plant floor.

He claimed that automotive parts manufacturers have some of the tightest delivery dates in the industry. This coupled with the fact that they have to profit off of very thin margins, makes it a perfect storm for being blindsided by loss or waste. He said it is one of the biggest daily risks to their business, and one that is extremely profitable when improved, and devastatingly costly when inconsistent.

Optimizing Performance and Uptime

Uptime is critical to ensuring that delivery is on time to your customers, but not only that, it’s essential for ensuring that you produce at a cost that is consistent with forecasts and projections. The big hits come when you find out about performance issues after it’s too late to fix them.

This COO went on to say that they were often finding that costs were inconsistent over time. When they explored why this was, they found out that they were getting behind so they had to run additional shifts to fulfill the orders on time.

They discovered this issue was directly correlated to uptime. They didn’t know when certain machines weren’t running and this was leading to inconsistencies in how they planned out the plant. They thought it was always running one way, when in reality it ran differently almost every day.

He claimed that once they were able to see when machines went up and down in real-time they could better account for how that may affect operations, logistics, and more. He said some issues were preventable and others weren’t, but that ultimately understanding the problem allowed them to be a smarter business.

These insights gave them an easy start to fixing the problem. Once you know why something is inconsistent, you can solve the problem. The COO admitted that this was often the hardest part.

“Once you know why something is wrong, you have the formula to justify any costs associated with fixing it”.

Reporting on Cell and Machine Levels

After our conversation, I actually thought of something else pretty interesting that likely has some pretty strong benefits for automotive parts OEE.

As we all know, most auto parts manufacturers set up cells of multiple machines to produce parts. Understanding OEE at the cell level is critical but you also need to understand how each machine in the cell is performing to diagnose bottleneck and pinpoint problems. It may not make sense to track OEE by machine but downtime by machine is critical.

For example, manufacturing engineers try to balance the cells as much as possible, but there is always a bottleneck. The bottleneck can change based on what is happening with each machine. If the first machine in a cell goes down for a few hours it will probably starve the rest of the line, including your bottleneck machine. Maintenance and supervisors need to know this as soon as possible to take action and prevent costly overtime or delayed deliveries.

Analytics to Save the Day

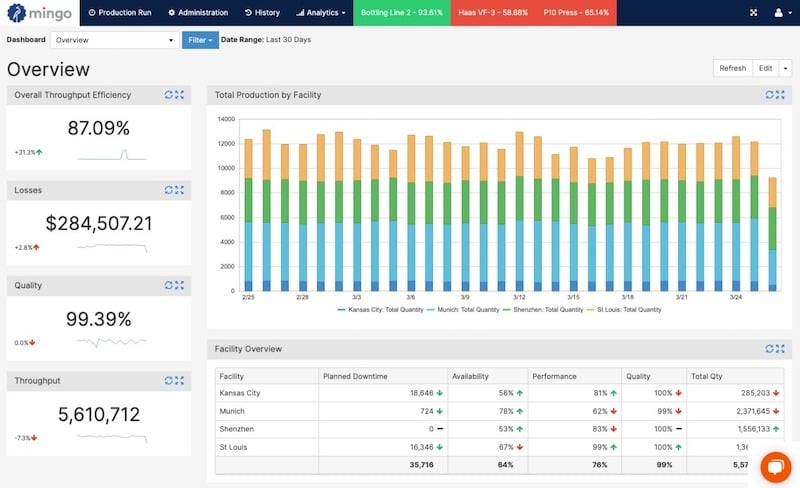

Ultimately, it comes back to the basics that we preach often. Data-driven lean manufacturing processes require some really fundamental data, in a simple way, to every stakeholder in the organization. The data isn’t just for the shop floor, or ops, or management. It’s for everyone.

If everyone can see a problem, identify it as it’s happening, then you solve for it in real-time; preventing significant costs. There are few that can benefit more from implementing as many of these practices as possible than automotive parts manufacturers.

Having a steady handle on uptime and performance can help you quickly identify inconsistencies costing you money, and essentially increase your margins while reducing your risk.