Many manufacturers are running on older machines that either does not have a PLC or have embedded sensors but no connectivity. These legacy machines are often critical to at least one part of the manufacturing process, maybe it’s that monster lathe built in the ’60s, “Ol’ Faithful”.

In this case, inexpensive hardware can easily be retrofitted to track cycle times and downtime or a simple device can be installed to read and transmit internal sensors.

We can also leverage products from Banner Engineering who produce wireless devices with sensors to count machine cycles through vibration and other data. It’s the closest thing to a peel-and-stick sensor on the market, can cost around a couple of hundred dollars, and will begin reporting in seconds.

Through calculations on machine cycles, we can determine downtime, with manually added downtime reasons, old machines can begin to provide valuable metrics on their performance and availability.

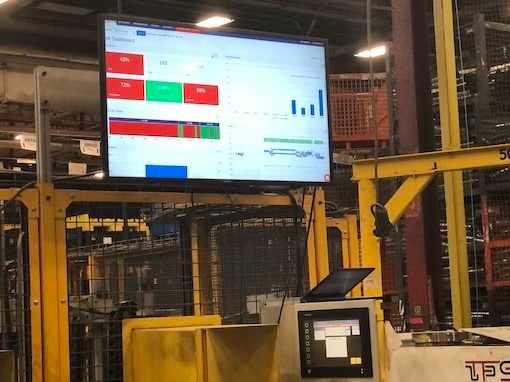

That data can be wirelessly transmitted to the Mingo application and within a few hours, Ol’ Faithful can be happily singing machine analytics with the rest of the line.